Introduction to Noma Fermentation

Noma, the renowned Copenhagen restaurant, isn’t just known for its innovative and exquisitely plated dishes; its revolutionary approach to fermentation is equally celebrated. This unique fermentation philosophy has significantly impacted the culinary world, inspiring chefs and food enthusiasts alike to explore the transformative power of this ancient preservation technique. It’s a method that elevates simple ingredients to unexpected heights of flavor and complexity.

Noma’s fermentation techniques didn’t spring up overnight. Its origins lie in a deep respect for Scandinavian culinary traditions, combined with a relentless pursuit of innovative flavor profiles. Chef René Redzepi and his team extensively researched traditional Nordic fermentation methods, adapting and refining them to suit their modern, experimental cuisine. This involved studying historical texts, collaborating with local food producers, and experimenting with a vast array of ingredients, resulting in a unique and highly refined fermentation program. The process is far from haphazard; it’s a meticulously documented and scientifically-informed approach.

Noma’s Fermentation Philosophy, Noma fermentation

Noma’s fermentation philosophy centers on harnessing the power of naturally occurring microorganisms to enhance the flavors and textures of ingredients. It’s not simply about preservation; it’s about transforming ingredients into something entirely new and exciting. This philosophy is underpinned by a deep understanding of terroir – the unique characteristics of a specific place and its impact on the flavor of food. Noma meticulously sources local, seasonal ingredients, ensuring that the terroir is reflected in the final dish. This commitment to local ingredients, coupled with their precise fermentation techniques, creates a unique culinary identity that is deeply rooted in its Scandinavian origins. The philosophy prioritizes natural processes, minimizing intervention and maximizing the potential of each ingredient.

Comparison with Traditional Fermentation Practices

While drawing inspiration from traditional fermentation practices, Noma’s approach differs in its level of precision and scientific understanding. Traditional fermentation methods often rely on intuitive knowledge passed down through generations. Noma, on the other hand, employs a more scientific approach, utilizing laboratory techniques to monitor the fermentation process, analyze microbial populations, and ensure consistent results. For example, while traditional sauerkraut fermentation might rely on ambient temperature and a basic understanding of salt concentration, Noma uses controlled environments and precise measurements to optimize the fermentation process and achieve specific flavor profiles. This scientific rigor allows Noma to push the boundaries of fermentation, creating unique and complex flavors that would be difficult to achieve through traditional methods alone. The scale of experimentation and the detailed documentation of the process also sets Noma apart, providing a wealth of knowledge for future culinary innovation. However, the core principles remain the same: utilizing natural processes to enhance the quality and flavor of food.

Key Ingredients and Microorganisms in Noma Fermentation

Noma’s revolutionary fermentation techniques hinge on a careful selection of both ingredients and microorganisms. The restaurant’s commitment to locally sourced, seasonal produce directly impacts the flavor profiles and microbial communities involved in the fermentation process. This precise control allows for a depth of flavor and complexity rarely seen in other culinary applications.

The success of Noma’s fermentations relies on a synergistic relationship between carefully chosen ingredients and specific microorganisms. The interplay of these elements creates a dynamic ecosystem that transforms simple ingredients into culinary masterpieces. Understanding these key components is crucial to appreciating the artistry and science behind Noma’s unique approach.

Primary Ingredients Used in Noma Fermentation

Noma’s fermentation processes utilize a wide range of ingredients, primarily focusing on seasonal vegetables, fruits, and seafood sourced from the local environment. This dedication to local sourcing ensures both freshness and a unique terroir that influences the final product. Common ingredients include various root vegetables like turnips and carrots, leafy greens such as kale and cabbage, and a variety of fruits depending on the season. Seafood, particularly shellfish, also plays a significant role, contributing unique umami notes and complex textures. The selection of these ingredients is meticulously considered, taking into account factors like ripeness, freshness, and potential microbial diversity.

Types of Microorganisms and Their Roles

A diverse range of microorganisms contributes to the unique fermentation profiles achieved at Noma. These include various species of bacteria, yeasts, and molds, each playing a distinct role in the transformation of the raw ingredients. For example, lactic acid bacteria are often responsible for the characteristic sourness and preservation of fermented vegetables. Yeasts contribute to the development of complex aromas and flavors, while specific molds might contribute unique textures and earthy notes. The precise mix of microorganisms varies depending on the specific ingredient and desired outcome, reflecting a deep understanding of microbial ecology. Noma’s chefs often work with naturally occurring microbial communities, carefully selecting ingredients that support the growth of beneficial microorganisms while inhibiting the growth of undesirable ones.

Sourcing and Selection of Ingredients for Optimal Fermentation

The sourcing and selection of ingredients are paramount to Noma’s fermentation success. Ingredients are chosen based on their inherent microbial diversity and their suitability for the desired fermentation process. The restaurant maintains strong relationships with local farmers and suppliers, ensuring access to high-quality, seasonal produce. Careful inspection and selection of ingredients are crucial to minimizing the risk of contamination and ensuring the success of the fermentation process. Factors like ripeness, texture, and the absence of any damage are meticulously assessed before ingredients are incorporated into fermentation processes. This ensures the consistent production of high-quality fermented products.

Noma Fermentation Techniques and Processes

Noma’s fermentation techniques are integral to their innovative and celebrated cuisine. Their approach goes beyond simple preservation; it’s a method of transforming ingredients, creating complex flavors and textures that define their culinary identity. Mastering these techniques requires precision, patience, and a deep understanding of microbial processes.

Lacto-Fermentation of Vegetables: A Step-by-Step Guide

Lacto-fermentation, a cornerstone of Noma’s fermentation program, relies on naturally occurring lactic acid bacteria to preserve and enhance the flavor of vegetables. This process is relatively straightforward but demands attention to detail for optimal results.

- Preparation: Begin by selecting fresh, high-quality vegetables. Thorough cleaning is crucial; remove any dirt or debris. Then, finely chop or shred the vegetables to increase surface area, facilitating bacterial growth. The size will depend on the vegetable and desired texture.

- Salting: Generously salt the vegetables, typically using 2-4% salt by weight. The salt draws out moisture, inhibiting undesirable bacteria while creating a brine that encourages beneficial lactic acid bacteria. Gentle massaging helps to evenly distribute the salt and extract the liquid.

- Packing: Pack the salted vegetables tightly into a clean, non-reactive container, such as a glass jar. Ensure the vegetables are fully submerged in their own brine. If necessary, add more brine or a weight to keep them submerged. Air exposure can lead to mold growth.

- Fermentation: Cover the jar loosely with a lid or cheesecloth to allow for gas release. Fermentation occurs at room temperature (ideally around 68-72°F or 20-22°C). The process typically takes several days to several weeks, depending on the vegetables and desired level of fermentation.

- Monitoring and Tasting: Regularly monitor the fermentation process. Taste the vegetables periodically to assess the level of sourness. Once the desired level of sourness is achieved, transfer the fermented vegetables to an airtight container and refrigerate to halt fermentation.

Comparison of Noma Fermentation Methods

Noma employs a variety of fermentation techniques, each tailored to specific ingredients and desired outcomes. The following table highlights key differences in these methods.

| Fermentation Method | Time (Days/Weeks) | Temperature (°C) | Environment |

|---|---|---|---|

| Lacto-fermentation (Vegetables) | 7-21 | 20-22 | Room temperature, anaerobic |

| Koji Fermentation (Soy Sauce) | 30-60+ | 25-30 | Controlled humidity and temperature |

| Vinegar Fermentation | 60-90+ | 25-30 | Aerobic, controlled temperature |

| Mushroom Fermentation | 14-28 | 18-22 | Room temperature, high humidity |

Controlling Temperature and Humidity During Fermentation

Precise temperature and humidity control are vital for successful fermentation at Noma. Fluctuations can significantly impact the microbial activity, potentially leading to undesirable flavors or spoilage. Noma likely utilizes a combination of techniques, including temperature-controlled rooms, fermentation chambers, and precise monitoring equipment. For instance, precise temperature control within a specific range is crucial for the development of desirable lactic acid bacteria in lacto-fermentation. Similarly, high humidity is often maintained for mushroom fermentation to prevent drying and promote optimal growth. Deviations from optimal temperature and humidity can result in slower fermentation, off-flavors, or even mold growth. The precise methods used are often proprietary, but the principle of controlled environments remains central to their approach.

Applications of Noma Fermentation in Culinary Creations

Noma’s innovative approach to fermentation isn’t merely a technique; it’s a fundamental element shaping the restaurant’s unique culinary identity. Fermentation profoundly impacts every aspect of their dishes, from the foundational flavors to the textures and aromas that tantalize the palate. This transformative process allows Noma’s chefs to unlock previously unrealized potential within ingredients, creating experiences far beyond the capabilities of traditional cooking methods.

Fermentation’s influence at Noma is multifaceted, enhancing both familiar and unexpected ingredients. The restaurant’s commitment to showcasing seasonal, locally sourced produce makes fermentation an ideal tool for preserving and transforming these fleeting treasures. The resulting dishes are not only delicious but also reflect a deep connection to the environment and a respect for the natural processes of transformation.

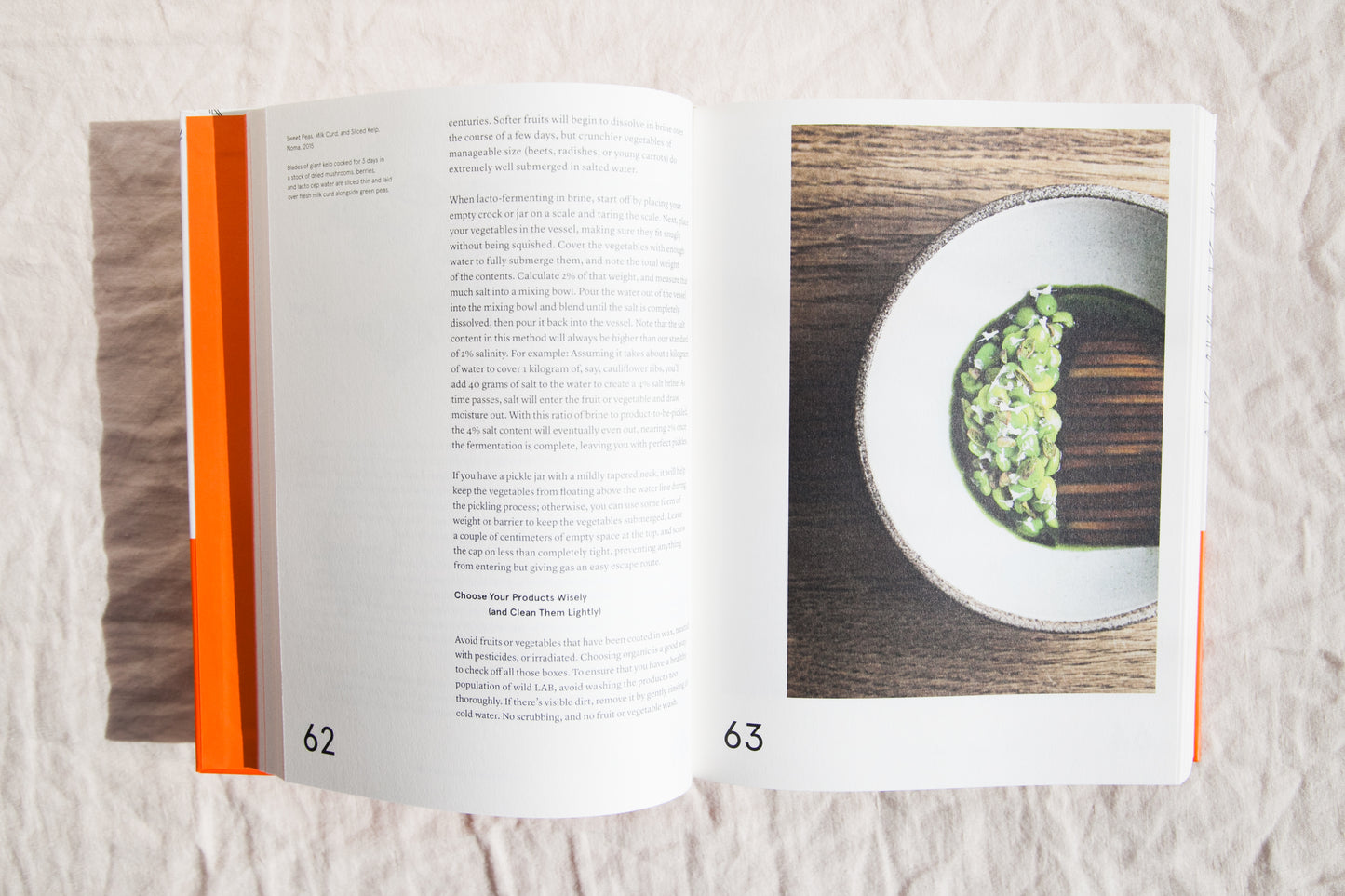

Examples of Noma Dishes Utilizing Fermented Ingredients

Noma’s menu is constantly evolving, but past examples highlight the breadth of fermentation’s application. Imagine a dish featuring fermented black garlic, its sweetness and umami notes contrasting beautifully with the delicate flavors of a seasonal vegetable. Or consider the textural complexity achieved through the fermentation of root vegetables, their earthy flavors intensified and their textures softened into a unique culinary experience. Fermented berries might add a surprising tartness and depth to a savory dish, showcasing the versatility of this process. These examples demonstrate how Noma uses fermentation to not only preserve ingredients but to create unexpected flavor combinations and textures.

Impact of Fermentation on Texture, Flavor, and Aroma

Fermentation dramatically alters the sensory properties of ingredients. Consider the transformation of cabbage into sauerkraut: the firm texture softens, while the flavor profile shifts from mild to complex, with notes of sourness and umami. Similarly, the fermentation of fruits might reduce their sweetness while adding a unique tanginess and depth. The aromatic compounds produced during fermentation also contribute to the overall sensory experience, often creating nuanced and complex aromas that enhance the dish’s appeal. At Noma, this transformation is meticulously controlled to achieve specific flavor profiles and textures, demonstrating the precision and artistry involved in their fermentation techniques.

A New Dish Incorporating Noma-Inspired Fermentation Techniques

This recipe showcases Noma’s philosophy by using fermentation to elevate simple ingredients into a complex and flavorful dish.

Fermented Carrot and Apple Salad with Spruce Tip Vinaigrette

This salad features fermented carrots and apples, creating a sweet and sour base that is balanced by the herbaceousness of the spruce tip vinaigrette.

Ingredients:

* For the Fermented Carrots and Apples:

* 1 kg carrots, peeled and julienned

* 500g apples (such as Granny Smith), peeled, cored, and julienned

* 50g sea salt

* 20g sugar

* 20g fresh dill, roughly chopped

* For the Spruce Tip Vinaigrette:

* 50g fresh spruce tips (ensure they are not from a treated area)

* 100ml apple cider vinegar

* 50ml extra virgin olive oil

* 10g honey

* Salt and pepper to taste

Preparation:

1. Fermentation: Combine the julienned carrots and apples with salt, sugar, and dill in a large glass jar. Press down firmly to submerge the vegetables in their own juices. Cover with a cheesecloth and leave at room temperature for 3-5 days, checking daily for fermentation activity (bubbles). Once fermentation is complete (indicated by a pleasant sour aroma and slight softening of the vegetables), refrigerate.

2. Vinaigrette: Combine spruce tips, apple cider vinegar, olive oil, and honey in a blender. Blend until smooth. Season with salt and pepper to taste. Strain the vinaigrette to remove the spruce tips.

3. Salad Assembly: Gently toss the fermented carrots and apples with the spruce tip vinaigrette. Serve immediately or chill for later. The dish can be garnished with toasted nuts or seeds for added texture and flavor.

The Science Behind Noma’s Fermentation Success

Noma’s revolutionary approach to fermentation isn’t just about creating delicious food; it’s a meticulous orchestration of scientific principles, leveraging the power of microorganisms to transform raw ingredients into culinary masterpieces. Their success lies in a deep understanding of enzymatic activity, microbial ecology, and the precise control of fermentation parameters. This allows them to achieve unparalleled levels of flavor complexity and textural nuance rarely seen in other fermented foods.

The unique flavors and textures achieved through Noma’s fermentation are a direct result of the controlled breakdown of complex molecules within the ingredients. This process is driven primarily by enzymes produced by the microorganisms involved in the fermentation. Enzymes act as biological catalysts, accelerating specific chemical reactions that modify the taste, aroma, and texture of the food. For example, proteases break down proteins into smaller peptides and amino acids, contributing to umami flavors, while lipases break down fats into fatty acids and glycerol, impacting both taste and mouthfeel. Carbohydrates are also transformed by various enzymes, leading to the production of organic acids, alcohols, and other flavor compounds. The precise blend of microorganisms dictates which enzymes are active and, consequently, the final profile of the fermented product.

Enzyme and Microorganism Roles in Molecular Breakdown

The microorganisms used in Noma’s fermentations, often a complex consortium rather than a single species, play a crucial role in breaking down complex molecules. Different microorganisms possess different sets of enzymes, allowing for a diverse range of biochemical reactions. Bacteria, yeasts, and molds, depending on the specific fermentation, contribute unique enzymatic activities. For instance, lactic acid bacteria are commonly used to produce lactic acid, lowering the pH and inhibiting the growth of undesirable microorganisms while simultaneously contributing to a characteristic tangy flavor. Yeasts, on the other hand, may produce alcohols and esters, adding fruity or floral notes. The interplay between these various microbial communities and their respective enzymes is what gives Noma’s fermented products their distinct character. The precise control over temperature, oxygen levels, and salt concentration allows chefs to fine-tune the activity of these microorganisms, guiding the fermentation towards a desired outcome.

Comparison of Microbial Communities in Noma Fermented Products

While the exact microbial communities employed by Noma are often kept proprietary, it’s understood that their approach involves a high degree of biodiversity compared to many traditional fermentation methods. Many traditional fermented foods rely on a limited number of dominant species. In contrast, Noma’s fermentations likely feature a more complex ecosystem of microorganisms, potentially including various bacteria, yeasts, and molds working in concert. This diversity allows for a wider range of enzymatic activities, resulting in a greater complexity of flavors and textures. This contrasts with simpler fermentations, like those used to produce sauerkraut (primarily Lactobacillus species), which exhibit a more limited flavor profile due to the less diverse microbial community. The high biodiversity also contributes to a more robust fermentation process, making it less susceptible to spoilage by undesirable microorganisms. The precise selection and management of this microbial ecosystem is a key element of Noma’s success.

Visual Representation of Noma Fermentation Processes

Understanding the visual aspects of Noma’s fermentation techniques is crucial to grasping the artistry and precision involved. Visual aids can clearly demonstrate the transformative power of fermentation, showcasing the subtle yet significant changes in ingredients over time. These visuals provide a deeper understanding of the process beyond the technical descriptions.

Microbial Growth in Vegetable Fermentation

Imagine a vibrant illustration depicting the initial stages of fermenting vegetables, such as cabbage for sauerkraut. The first image shows tightly packed, fresh cabbage leaves, their vibrant green color unblemished. The second image, taken a few days later, shows the cabbage slightly softened, with a visible sheen of liquid forming around the leaves. This liquid, the brine, is teeming with lactic acid bacteria, initially invisible to the naked eye but represented visually by small, subtly glowing dots interspersed among the cabbage. A third image, after a week or more, showcases the cabbage transformed. The color has deepened, perhaps to a yellowish-green, and the leaves are noticeably softer. The glowing dots representing bacteria are now more numerous and larger, illustrating the exponential growth of the microbial population. This visual progression clearly demonstrates the dynamic nature of fermentation and the visible changes brought about by microbial activity.

Texture Changes During Fermentation

A series of close-up images can effectively illustrate the textural transformations during fermentation. The first image might feature a firm, smooth piece of root vegetable, like a carrot, before fermentation. The second image, taken mid-fermentation, shows a slightly softened carrot, with a subtle change in surface texture. Perhaps small fissures are visible, or the surface is less glossy. The final image showcases the fermented carrot. The texture is noticeably altered—it might be softer, more pliable, or even slightly spongy, depending on the specific fermentation method and duration. The color might also have deepened or changed slightly, providing further visual cues to the transformation. These images highlight the changes in the physical structure of the ingredient as a direct result of the fermentation process.

Noma Fermentation Equipment and Tools

A detailed illustration should showcase the range of equipment employed in Noma’s fermentation processes. This could include various sized glass jars, clearly labeled with their specific uses (e.g., for vegetable fermentation, for dairy fermentation). The illustration might also depict fermentation crocks, traditional earthenware vessels that maintain a consistent temperature and promote anaerobic conditions ideal for fermentation. Other essential tools, like weights for submerging vegetables in brine, thermometers for precise temperature monitoring, and airlocks to control the environment, should also be clearly illustrated. Finally, the image should include small details like labels indicating the fermentation timeline, temperature settings, and the specific ingredients undergoing fermentation. This visual representation emphasizes the importance of controlled environments and specialized equipment in achieving consistent and high-quality fermentation results.

Challenges and Considerations in Noma-Style Fermentation

Noma’s innovative fermentation techniques, while yielding exceptional culinary results, present unique challenges. Mastering these processes requires meticulous attention to detail, a deep understanding of microbiology, and consistent adherence to rigorous hygiene protocols. Failure to do so can lead to spoiled batches, off-flavors, and even potential health risks. This section will explore some key challenges and offer strategies for mitigation.

Noma fermentation – The inherent complexity of Noma’s fermentation methods, which often involve multiple ingredients and extended fermentation periods under varying conditions, increases the probability of encountering problems. These challenges are not insurmountable, however, and with careful planning and execution, successful outcomes are achievable.

Contamination Control

Contamination is a significant risk in any fermentation process, and Noma-style fermentations, with their diverse microbial ecosystems, are particularly vulnerable. Unwanted microorganisms, such as molds, yeasts, or bacteria, can compete with the desired cultures, producing undesirable flavors, aromas, and potentially harmful toxins. Maintaining a sterile environment throughout the process is crucial. This includes sanitizing all equipment thoroughly before use, employing aseptic techniques during ingredient handling and transfer, and monitoring fermentation vessels regularly for any signs of contamination. Early detection of contamination is key, often indicated by changes in odor, texture, or appearance of the fermenting material. Discarding contaminated batches immediately is essential to prevent further spread.

Unwanted Flavors and Off-Notes

The delicate balance of flavors in Noma’s fermentations can be easily disrupted. Factors like the starting quality of ingredients, fermentation temperature, and duration can all influence the final flavor profile. Unwanted flavors can result from improper ingredient selection, excessive fermentation time, or the presence of undesirable microorganisms. Troubleshooting involves careful analysis of the fermentation process, identifying potential points of failure, and adjusting parameters accordingly. For example, a sour or acidic taste might indicate excessive lactic acid bacteria activity, while a bitter taste could suggest the growth of undesirable yeasts or bacteria. Taste testing throughout the fermentation process is critical for early detection of off-notes.

Hygiene and Safety Protocols

Rigorous hygiene and safety protocols are paramount in Noma’s fermentation practices. The handling of raw ingredients, the maintenance of clean equipment, and the proper disposal of waste are all critical to prevent contamination and ensure food safety. Personnel should be trained in proper sanitation techniques and the use of personal protective equipment (PPE), such as gloves and masks. Regular cleaning and disinfection of fermentation vessels, tools, and work surfaces are crucial. Moreover, accurate temperature monitoring and control are vital, as temperature fluctuations can affect microbial growth and potentially lead to the production of harmful toxins. Following established safety guidelines and implementing a robust quality control system are essential to minimize risks and ensure the safety of the final product.